Tabletop

Technical Specification

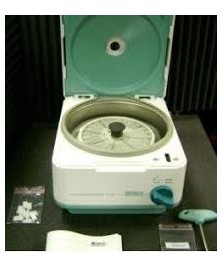

MEDITRONIC-BL-S HIGH SPEED CENTRIFUGES WITH MICROPROCESSOR CONTROL

1. This is a potable brushless induction motor centrifuge for a hospital laboratory

2. Will be used in the laboratory for separating components of body fluids of different densities.

3. The desired maximum speed is 8,000RPM

4. Speed (RPM) is not greater than ±5% of the displayed speed.

5. The tabletop centrifuge has a six place rotor for 2ml to 10ml tubes

6. Holds a maximum size of 16mm x 110mm test tube

7. Supplied with the test tube adapters

8. The tabletop centrifuge has a programmable digital adjustable in one minute increments.

a. The timer has a timing range of at least one hour.

b. The timer accuracy should be within ±2%.

9. The centrifuge has an alert indicator for imbalance, current, and lid open.

10. The centrifuge has an alert indicator when cycles completely stop.

11. The centrifuge will not operate with lid open. It is preferred that the centrifuge have a lid interlock.

12. The proposed centrifuge have the following parameters:

a. Maximum speed (approximately 8000 ±10% RPM)

b. Rotational centrifugal force (RCF) (approximately 7806g)

c. Type of rotor head (swinging bucket)

d. Acceleration time of 28sec

e. Stopping time 20sec

f. Braking type should be electric

g. Display type digital

h. RPM or rotor calibration method (e.g., tachometer)

13. The following accessories are included:

a. Ten graduated centrifuge tubes each for the 2ml, 5ml and 10ml tube sizes

b. Centrifuge tube rack to hold the 2ml, 5ml and 10ml centrifuge tubes.

c. Ten each of chemically resistant sealing cups

14. The supply shall include:

a. Installation

b. All relevant (standard and optional) accessories

c. replacement parts for 2 years warranty maintenance,

d. spare-parts and maintenance tools for at least 5years post warranty maintenance,

e. at least two years warranty

f. user training for laboratory staff

g. technical/maintenance training for engineering staff

h. copy of ervice/maintenance/technical manual

i. two copies each of operation manual

15. Bidder shall provide the complete list with part numbers and prices for all recommended replacement/spare parts

16. Bidder shall indicate the local availability and cost of

a. Maintenance service

b. spare-parts

17. Electrical Safety

a. The tabletop centrifuge should be provided with a line (power) cord of acceptable durability, quality, length, and ampacity and should be secured with adequate strain reliefs.

b. The centrifuge should include, or the seller should offer, power plugs that are sufficient for the maximum voltage and current of the unit.

c. The chassis should be grounded, and grounding resistance should not exceed 0.15(

d. If the centrifuge is double insulated, it should be so labeled.

e. Electrical leakage current from the chassis of the centrifuge should not exceed 500(A.

18. Effects of Fluids

a. Operator safety and system performance should not be adversely affected by fluid spills.

b. If the centrifuge is affected, it should fail safely.

19. Over-current Protection

a. Loss of power to other equipment on the same branch circuit due to internal equipment faults should be prevented by using fuses or circuit breakers that are clearly labeled and easy to replace or reset.

b. If fuses are used, a spare fuse should be provided in a labeled holder located next to the main fuse holder. Permanent markings near each fuse holder should indicate fuse ratings.

20. Line Voltage Variation

a. The centrifuge should operate satisfactorily at line voltages from 12.5% to +8% of nominal line voltage of 240volts.

b. The centrifuge should not be damaged by voltages from 21% to +12.5% of nominal voltage of 240volts.

21. Electromagnetic Interference (EMI)

a. The centrifuge's performance should not be affected by EMI radiated or conducted through the power lines from another device.

b. If the centrifuge is affected, it should fail safely.

22. Construction Quality

a. The tabletop centrifuge should have no sharp edges.

b. All external components should be securely mounted.

c. The centrifuge should be secure and provide adequate protection against moving and electrically energized parts.

d. The centrifuge should be well constructed with durable materials to withstand typical abuse and cleaning.

e. Switches, knobs, and other controls should be designed for conditions of heavy use.

23. Controls

a. The controls (e.g., switches, knobs) should be visible and clearly identified, and their functions should be self-evident.

b. Device design should prevent misinterpretation of displays and control settings.

c. Switches and controls should be protected against accidental setting changes (i.e., due to someone brushing against the panel).

d. Controls should be sealed against penetration of liquids.

24. Labeling

a. Labels and markings should be clear and legible.

b. Labels and markings should be durable enough to withstand routine cleaning and normal wear.

c. Appropriate warning legends should be provided on the centrifuge.

25. Ease of Use

a. The tabletop centrifuge should be simple to use, operate, and maintain.

b. Abbreviated operating instructions should be included on or with the centrifuge (e.g., on a laminated card attached to the centrifuge).

c. The centrifuge should be easy to clean.

d. The centrifuge should be designed for easy access to serviceable parts.

-

Clinical Breast Trainer

Clinical Breast Trainer

-

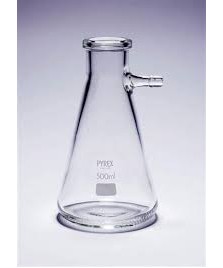

BUCHNER FLASK

CORNINGS PYREX ® BUCHNER

-

3M FACE MASK

3M FACE MASK

-

SEKUROKA®-SAFETY SPECTACLE

SEKUROKA®-SAFETY

SPECTACLE

-

WATER BATHS FOR FUME HOODS

WATER BATHS FOR FUME HOODS 1031 /1032

-

GFL WATER BATHS 7 LITER

GFL WATER BATHS 7 LITER

-

Theatre Gown

Theatre Gown

-

Ohaus Harvard Trip Mechanical...

Ohaus Harvard Trip Mechanical Double Beam Balance

-

ACCOSSON DEKAMET SPHYGMOMANOMETER

ACCOSSON DEKAMET SPHYGMOMANOMETER -

HAEMATOKRIT 210 WITH ROTOR

HAEMATOKRIT 210 WITH ROTOR

-

Cadiology Stethoscope

Harvey DLX Cardiology Stethoscope

-

Electronic Stethoscope

Littmann® Electronic Stethoscope

Model 4000WS