Autoclave

Technical Features

PRIORCLAVE 100L AUTOCLAVE

The Priorclave 100liter Autoclave offered provides the ideal solution to the autoclaving needs of most laboratories and pharmacy The Priorclave autoclaves are ideally suited for use in a wide range of sterilizing applications such as: media preparation, liquids and diluents, waste, glassware, instruments, apparatus and healthcare.

Features :

• Operation up to 140C - 2.5 Bar

Large diameter chamber giving 20% more loading area than conventional models.

Quickseal 2 single action door closure system

• Steam generated within the chamber (electrically heated models) - Direct steam heated models available

• Complete with thermocouple entry and test ports

• Forced air cooling as standard helping to reduce cycle times

• Automatic timed freesteaming as standard for improved air removal and sterilising performance

• Delayed start and media warming function as standard for ready to pour media at the start of the day

Chamber Volume: 100L, Floor Mounted, Horizontal

The Priorclave Autoclave provides steam sterilization based on:

Length of time in the cycle

Temperature

Pressure

Steam

A. CHAMBER CONSTRUCTION

Chamber is constructed with e Nickel material. The welded chamber, doors and jackets must meet AASME, AAMI, EN285, EN554, UL, CE0123 requirement and ISO 900:2000; ISO 1348 certified.

B. CONTROL

Tactrol Microprocessor control system Microprocessor controlled and tamper proof security mechanism.

The control system is isolated from steam and heat.

All information and alarms are provided in complete messages and can be printed form the inbuilt printer.

The Tactrol Microprocessor Control system provides the following alarms;

Vessel Flood

Steam Table Deviation

Chamber drain Probe

Under Temperature

Cycle Failure

5. The unit has Manual controls for use as backup and provided at safe locations for easy access.

5. Door(s)

1. Epoxy coated panels and frame members are treated with the unique BioCote® anti-bacterial agent, which is effective against all bacteria and fungi including MRSA Door frames are anti-corrosive.

2. The Autoclave door is designed with independent control features that provide for safety.

a. A thermal cooling lock, preventing the door from being opened until the contents have cooled to a safe temperature is also fitted along with a pressure interlock.

b. A thermal cooling lock, preventing the door from being opened until the contents have cooled to a safe temperature is also fitted along with a pressure interlock.

c. Visual non-electrical chamber gauge that identifies pressure in the chamber.

D. MOUNTING

The sterilization comes with a stainsless steel stand which is anti corrosive.

ELECTRICAL POWER :: 3Ph, 415V/50Hz, 60 – 100A

COMPRESSED AIR REQUIREMENT : 6 – 8 Bar

STEAM GENERATOR : 18 – 36KW

TYPE OF WATER: Tap Water Supply, Maximum Hardness: 0.7 – 2.0 mmol/L

WARRANTY

Warranty period: 36months

Cost of maintenance per year of operation after warranty must be provided. (8% of Product cost)

Cost of installation and training must be included in the office price (Inclusive of price offer.)

The Biomedical engineering department of Beautiful Creations will supply, install, maintain and provide after sales service on all autoclave supplied .

-

Obstetrical Forceps

OBSTETRICAL FORCEPS

-

Conforming Bandage

CONFORMING BANDAGE

-

Nitrile Disposable Gloves

THE LIFECARE NITRILE DISPOSABLE GLOVES.

-

Bone Cutting Forceps

BONE CUTTING FORCEPS

-

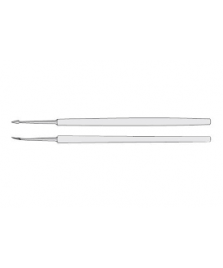

Acrylic Timmer Burs

Acrylic Timmer Burs

Assorted Shapes

-

Roux Retractos

Roux Retractos

-

Episiotomy Scissors

EPISIOTOMY SCISSORS

-

Ptosis Forceps

Ptosis Forceps

-

-

Vectis Spoon Retractors

Vectis Spoon Retractors

-

Tongue Forceps

TONGUE FORCEPS